Robots have been used to clear nuclear waste for years. Giles Brown speaks to the man heading up the robotic clean-up mission at Sellafield

Robots have been helping their human colleagues with the clean up mission at Sellafield for well over a decade.

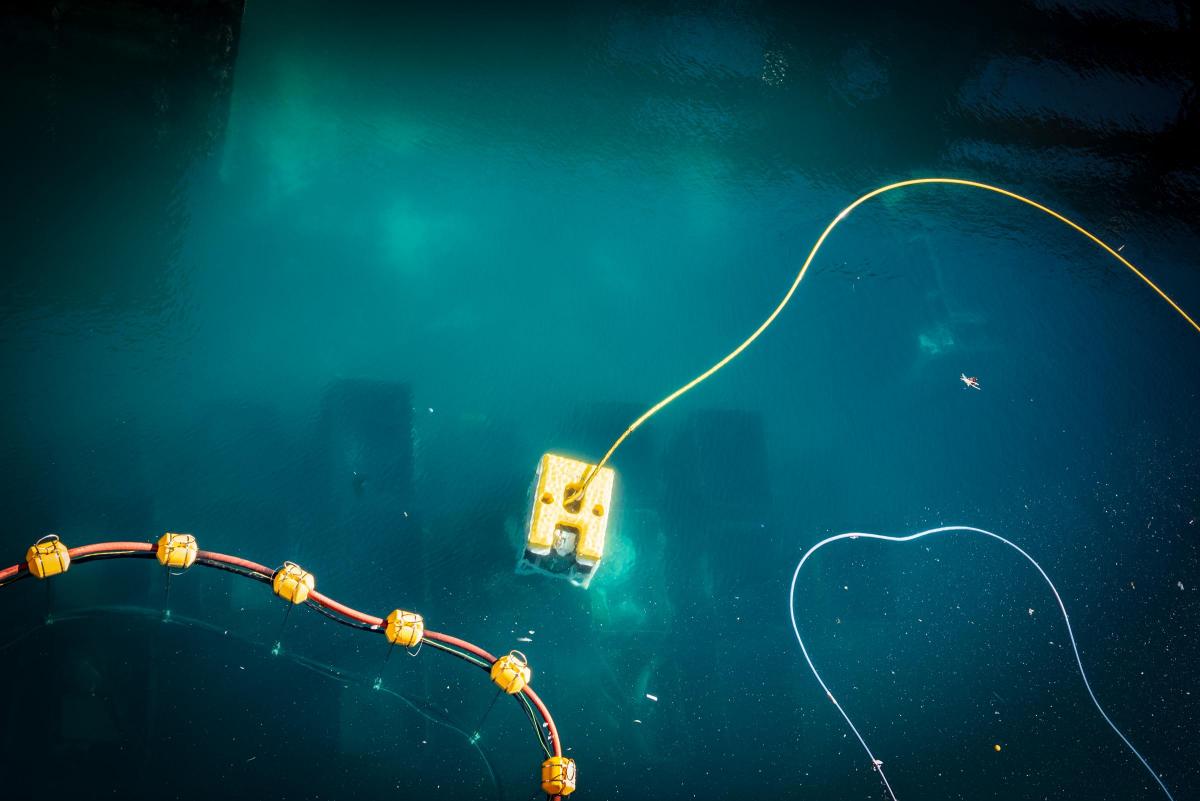

They are busy at work in ponds used to store radioactive waste and debris and also in other facilities where robots with lasers are used to cut hazardous material.

Elsewhere, robotic manipulators are being developed to improve safety by replacing human hands in the ‘gloveboxes’ which access hazardous environments using a pair of gloves embedded into a secure barrier.

Four-legged ‘robot dogs’ survey and inspect hazardous areas, while overhead drones are carrying out aerial inspections several times a day.

Robots come with the obvious advantage that they are not susceptible to radiation poisoning and the cost of any damage they do suffer is measured in pounds Sterling instead of injury or loss of life

Two years ago Rav Chunilal was appointed as head of robotics and artificial intelligence as part of a move by Sellafield Ltd and the Nuclear Decommissioning Authority (NDA) to focus on investing in robotics, autonomous systems and artificial intelligence as a key part of accelerating the safe delivery of the mission at the site.

"We started looking at our challenges in a slightly different way, to help move our workforce out of harm's way and improve productivity efficiencies,” says Rav.

His work was initially focused on Sellafield itself and now incorporates other NDA sites and the wider nuclear sector and supply chain.

He says previously teams of people at Sellafield were working on various divisions such as flying drones, land-based robots and artificial intelligence.

He has been acting to unite different teams to work together and share knowledge more effectively, not only at Sellafield but also with other nuclear sites around the UK and vice versa.

"What we're trying to do is make the world a smaller place so that everyone can operate a bit more freely, explore where the robotic and AI developments have happened and then share that learning far and wide,” says Rav.

Sellafield and the NDA are also expanding their mission to share knowledge in the form of quarterly online forums bringing together operators from across the industry.

The forums are continuously growing in membership and regularly attract over 120 participants.

"You'll always have a variety of challenges being shared from different teams across the NDA Group," says Rav.

"The beauty is it's creating new contacts and connections within our organisations, and importantly improved connections within the supply chain and with academics.”

He says the forums have already led to conversations between SMEs and academics about how R&D projects can be commercialised for use at other nuclear sites and other industries.

"What we're doing is creating the platform to initiate and catalyse robotics and AI developments and deployments to happen,” he says.

“It's started on a relatively small scale for now but has huge opportunities to grow much further.”

He says facilities such as RAICo1, in Whitehaven, will play a key role in his work.

RAICo1, which is due to formally open this spring, is a joint initiative developed by Sellafield Ltd and the NDA in collaboration with the UK Atomic Energy Authority, Manchester University and the National Nuclear Laboratory.

It will act as a hub for Sellafield Ltd, its supply chain and academic institutions to develop and test robotics and AI technology in Cumbria.

Rav says the opportunity for the sector to collaborate and work together will accelerate the pace the technology can be developed and avoid delays caused by making adaptations after it is deployed.

"We don't want to just have knee jerk reactions to challenges,” says Rav.

“We want to be able to have it built into our intrinsic systems and plans, so that when we're thinking about the design of future facilities, robotics is something that they think of first.”

He says as more robotics and AI systems are deployed, it allows more of the workforce to be upskilled to work in associated creative roles such as coding, designing, development, training and maintenance.

"Robotics and AI deployments in nuclear is all around moving our workforce out of harm's way and it's taking some of the more difficult and repetitive tasks from the workforce and providing opportunities to train in more highly skilled jobs that are more rewarding. It's not taking your job away and making you redundant, it's creating a more rewarding job in the region.

"Ultimately, we want to get to a position where automated robotic systems and AI are the first choice for the nuclear sector, so that the activities that are undertaken on our site can be optimised and automated so that we can improve workforce productivity and safety.

"I see us deploying robotics to help us knock years or decades off our lifetime plan. As we get this right across the NDA group, working collaboratively with other sectors, I think it could be a massive win, not just for nuclear, but for the UK as a whole.”

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here