BAE Systems are concluding their work wit Furness Plastics making protective equipment for key workers after creating around 2000 masks during the coronavirus pandemic.

At the start of the pandemic an appeal for help from the NHS in south Cumbria for vital personal protective equipment led to the creation of a successful collaboration between engineers at BAE Systems in Barrow and Furness Plastics.

Working together the team came up with a plan for a protective mask for NHS staff treating Coronavirus patients. Within a matter of days a design was agreed.

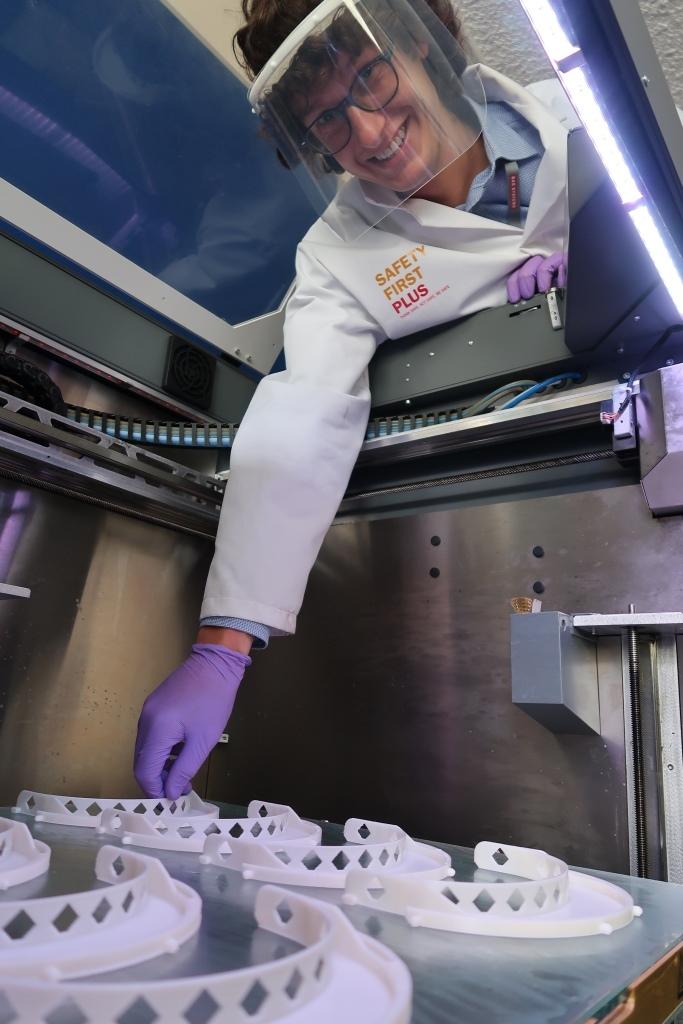

A shield made of polypropylene connected to a plastic frame could be mass produced in Barrow using technology already available.

The frames were created using a network of 3D printers on the BAE Systems site with local supplier Furness Plastics producing the transparent shield. 50 shields a day could be produced and supplied to a grateful NHS.

BAE Systems employee Sean Leighton was among the engineers who worked throughout the period to keep the printers serviced and topped up with the raw material needed to maintain production.

"Keeping them running became a labour of love because we knew how much the equipment was in demand," Sean said.

The specialist in material engineering spent evenings and weekends returning to the shipyard to check on the printers' progress.

"We got into a real routine and making the connection with Furness Plastics helped us produce a really good product," added Sean.

Bob Kett, the owner of Furness Plastics, said: "Many of the available face shields at the time were disposed of after single use so together with the NHS, we researched a clear material which could be disinfected and reused.

"Undertaking all this work has been a huge effort for Furness Plastics and special tributes should be paid to Maureen McBratney and David Winder for their diligence and effort.

"Assisting BAE systems to provide 2000 face shields for NHS use has, we hope, in some way helped to repay the fantastic efforts and sacrifices their staff have given."

Neil Doherty, BAE Systems' corporate social responsibility advisor said: "This current collaboration may be coming to an end however our ability to not only design but work out how to manufacture a vital piece of kit and to provide a solution so fast may well be useful in the future."

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here